Learn about our welding equipment history

Industrial manual arc welding machine

Using thickened heat sinks and 200 type large fans, the heat dissipation effect is better, ensuring that the machine can operate stably under high load. It is widely applicable, suitable for field operations and other scenarios requiring high load and stable current output, with high practicality and durability.

Efficient welding: Fast welding speed, significantly improved work efficiency. According to user feedback, using this equipment for welding operations can improve work efficiency by 2-10 times, saving a lot of time and cost for enterprises.

Strong adaptability:It can maintain stable welding performance in various environments, especially suitable for use in harsh environments.

Lightweight design The welding gun system of the Blue Lian laser welding machine adopts a lightweight design, the gun head is light in weight, and it is convenient for the operator to hold it for a long time; the wire feeder system maintains smooth feeding during welding, making the welding process smoother and more efficient.

Automatic platform welding machine

This model adopts air cooling mode, greatly reducing the size and further reducing the weight of the machine. It adopts system linkage wire feeding and air pressure monitoring, equipped with the 5th generation handheld welding gun head, with double protective lenses, drawer rotation + drawer type protective lenses, which can be rotated 6 times, increasing the service life by 6 times, durable and double protection; unique focal length adjustment structure, easy to adjust the focal length and replace the gun nozzle.

Efficient welding:Fast welding speed, significantly improved work efficiency. According to user feedback, using this equipment for welding operations can improve work efficiency by 2-10 times, saving a lot of time and cost for enterprises.

Strong adaptability:It can maintain stable welding performance in various environments, especially suitable for use in harsh environments.

Lightweight design:The welding gun system of the Blue Lian laser welding machine adopts a lightweight design, the gun head is light in weight, and it is convenient for the operator to hold it for a long time; the wire feeder system maintains smooth feeding during welding, making the welding process smoother and more efficient.

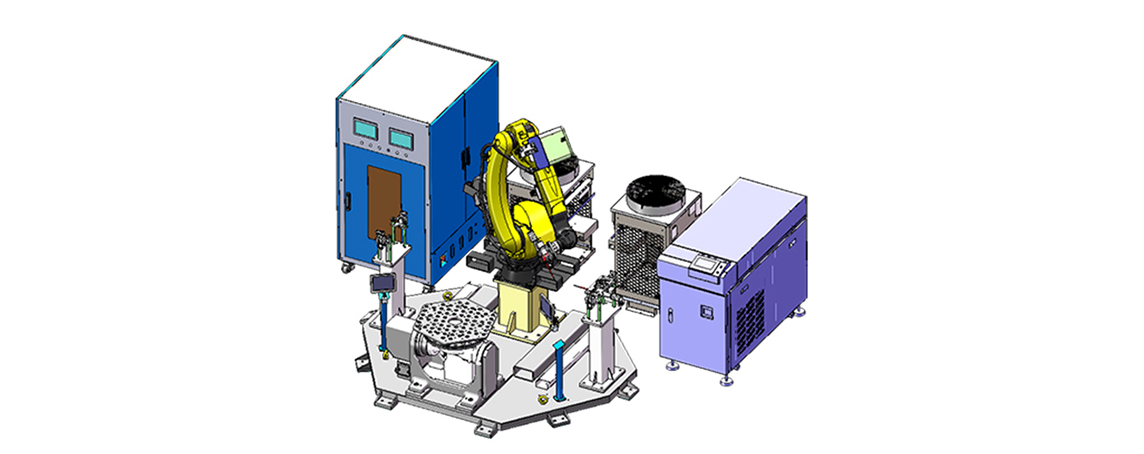

Automatic platform welding machine

The automatic platform welding machine adopts advanced sensor systems and intelligent control systems to achieve highly precise welding. It can automatically adjust welding parameters according to different welding materials and requirements, ensuring welding quality is not affected by the environment, achieving stable welding results.

Fast welding speed:Compared to other welding processes, the platform laser welding machine is 3-10 times more efficient.

High weld strength:The only welding process where the weld strength can surpass the base material.

Uniform and smooth welds:Post-weld treatment is simpler, saving time and money.

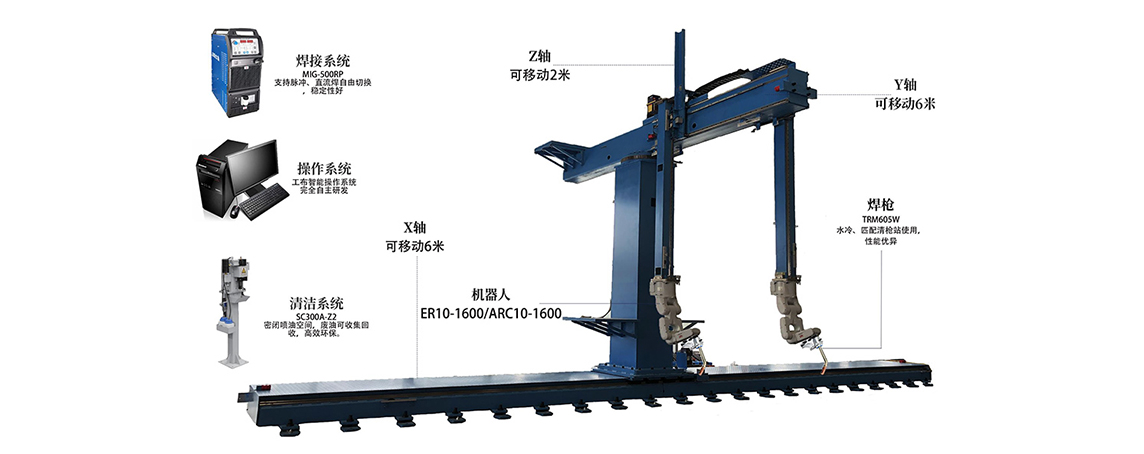

Sheet metal laser workstation

High precision and high-quality welding, capable of achieving high-precision positioning and welding, avoiding errors and deformations that may occur in traditional welding methods. Laser welding has fast speed and a small heat-affected zone, resulting in high-quality welds and minimal welding deformation.

High strength and corrosion resistance:The joint strength of laser welding is high, capable of withstanding significant pressure and stress. Additionally, due to the small heat-affected zone during welding, material oxidation and degradation at high temperatures are reduced, improving material corrosion resistance.

High efficiency and energy-saving:Laser welding concentrates energy, completing welding in a short time, reducing energy waste. Additionally, laser welding can achieve automation and continuous production, improving production efficiency.

Wide range of applications:Suitable for welding various metal materials, such as stainless steel, carbon steel, aluminum, etc. It is also suitable for various welding needs, such as spot welding, butt welding, lap welding, etc.